Does your operation require accurate drill logs? If not, it can be a significant liability. Not identifying changing geologic conditions can lead to misfires, flyrock, high air overpressure and poor blast performance.

Does your operation require accurate drill logs? If not, it can be a significant liability. Not identifying changing geologic conditions can lead to misfires, flyrock, high air overpressure and poor blast performance.

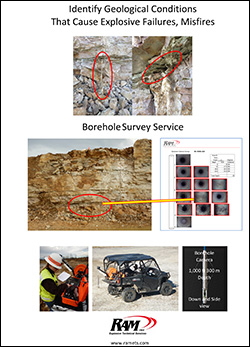

Borehole camera surveys help identify and confirm changing conditions such as soft seams and cavities providing critical information needed for safe and optimized blasting. Surveys can be used to verify measure-while-drilling reports and manual drill logs to site conditions.

Our services provide down-hole and side view, video and still images to help the driller and blaster better understand the geologic condition to improve drill log accuracy, blast safety and performance.

A down-the-hole camera is used to clearly view and accurately record the physical location of geological strata, weak/strong boundaries, ore/waste boundaries, coal seams, top of coal, free-surface of water or ingress points, in-situ fractures, cavities and irregularities. This information is quite valuable to engineers, geologists, blasters and other professionals who need to modify shot designs or to investigate geological conditions.

We provide high resolution video surveys of dry or water filled boreholes with diameters as small as 2.5 in (63.5 mm) and to a maximum depth of 1000 ft (300 m).

During the video surveying of a borehole, the depth is continuously displayed so notes on borehole conditions can be recorded. Also, the camera can be toggled from a down-the-hole view to a side-view, with the high intensity LEDs, so significant changes in the borehole can be recorded. The side-view camera has continuous 360 degree rotation to clearly record the full perimeter of the borehole.